Hella: Tire Pressure Monitoring System Basics

Got Me Under Pressure

From the end of 2014, all new vehicles have a tire pressure monitoring system on board as standard and Hella has some insights into what it is and how it works. For starters, the system provides a warning about insufficient tire pressure and protects the driver against increased fuel consumption and tire damage. None of which are bad things.

Tire pressure is an essential safety factor of a vehicle. The most common tire damage can be traced back to a gradual pressure loss. This is often noticed by the driver of the vehicle when it is too late. Insufficient tire pressure causes increased fuel consumption and poor driving characteristics. Increased tire temperature and greater wear are also linked to this. Insufficient tire pressure may cause the tire to suddenly burst. This is an extremely high safety risk for all those in the vehicle. This is why tire pressure monitoring systems (TPMS) have been mandatory since November 2014 for all new vehicles in the EU.

https://www.youtube.com/watch?v=qO7cRMIjCHg

The general parts aftermarket also offers different systems for retrofitting. Tire pressure monitoring systems monitor the tire pressure and tire temperature. tire pressure monitoring systems have been on the market for a while, mostly in top-end vehicles. In the USA, they have been mandatory for new vehicles for several years. It is therefore time for all workshop staff to familiarize themselves with this topic. Even during a wheel change, a lack of knowledge about the systems can lead to impairment of the tire pressure monitoring system.

You can split them into two fundamentally different systems: indirect and direct tire pressure monitoring systems.

The Indirect Approach

In indirect measuring systems, the pressure is monitored using ABS sensors on the vehicle. The ABS control unit detects the pressure loss of a tire through the different rolling circumference. A tire with a low air pressure makes more revolutions than one with the correct air pressure. However, these systems are not as precise as direct measurement systems, and require a pressure loss of approx. 30% before there is a warning message. The advantage is the relatively low price as numerous vehicle components already in place can be used. The only things required are adapted ABS software and an additional display in the instrument unit.

Taking the Direct Route

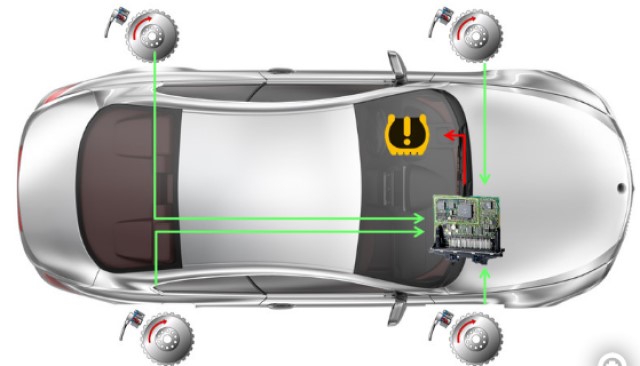

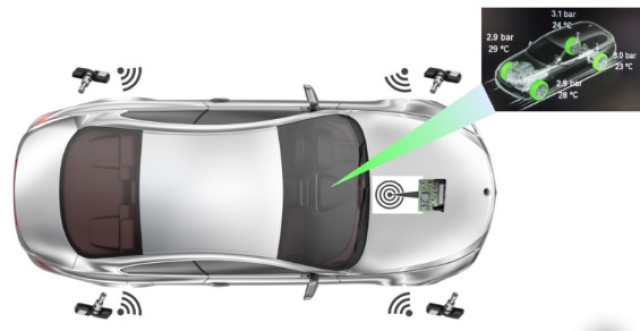

Direct measurement systems are considerably more precise, but also involve more outlay, and are therefore more expensive. Here, a battery-powered sensor is located in each wheel. This measures the temperature and the pressure of the tire, and transfers the measured values wirelessly to the tire pressure monitoring system control unit and/or the display unit. One or more antennas transmit the radio signal.

Direct systems compare the tire pressure with a reference value stored in the tire pressure monitoring system control unit. This has the advantage that pressure losses of several tires can be detected at the same time. This may mean that, following a tire change, a re-adjustment (calibration) or re-coding of the sensors is required.

A further disadvantage of the direct measuring systems is that the batteries have to be replaced after approx. 5 – 10 years. As, depending on the manufacturer, these form a unit with the sensors, this often means complete replacement of the sensor unit.

If the batteries have to be replaced, this is shown in a timely manner by the display unit, meaning that a sudden system failure is avoided. When changing from summer to winter tires, it should be ensured that additional wheel sensors are attached, or that existing sensors are modified. Certain important points should be noted so that no damage or functional problems occur during tire fitting.

COMPANY DETAILS |

|

|

Company |

Hella Group |

|

Website |

|

|

Connect |

|

|

|

|

|

Contact |

|

|

Address |

Rixbecker Str. 75 |

|

59557 Lippstadt, Germany |

ABOUT Hella Group®

HELLA is a global, family-owned company listed on the stock exchange that employs some 34,000 members of staff at over 125 locations in more than 35 countries. The HELLA Group develops and manufactures lighting and electronic components and systems for the automotive industry, and also has one of the largest trade organizations for automotive parts, accessories, diagnosis and services within Europe.